Your current location:Home>Product>Mineral processing equipment

Direct deal Quality Assurance Quick response Service worry free

Production capacity:

Feed particle size:

Applicable materials:

![]() Do you need help? WhatsApp: +8615038150366

Do you need help? WhatsApp: +8615038150366

sales@trifumac.com Hotline:+8615038150366

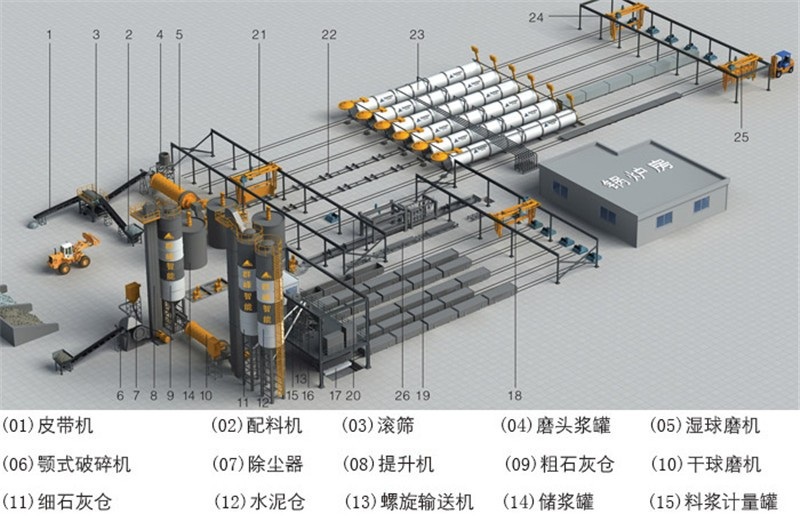

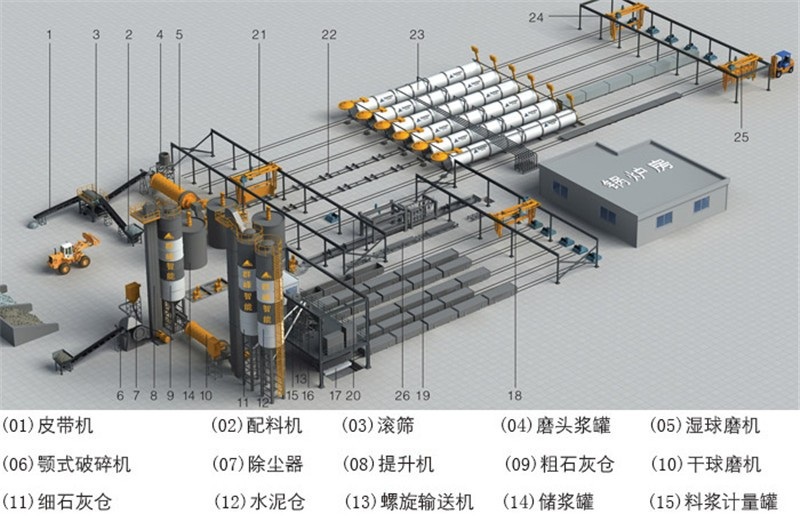

Raw material treatment, pouring, cutting and steaming, etc. The connection between the complete set of gas brick equipment is scientific and close, the complete set of production line operation is relatively simple, the degree of automation is high, and the investment is moderate, so the sales volume of 50,000 cubic meters of gas block equipment is relatively large in these years. In the cutting process, the user can choose the air flip cutting, ground reverse cutting and other different processes according to the need, the advanced distributed cutting unit design makes the entire cutting process (including flipping, longitudinal cutting, die cutting) in different links to complete, cutting, walking control located in the same device, so the equipment structure design is more simple, the operation is further simplified.

Raw material treatment, pouring, cutting and steaming, etc. The connection between the complete set of gas brick equipment is scientific and close, the complete set of production line operation is relatively simple, the degree of

automation is high, and the investment is moderate, so the sales volume of 50,000 cubic meters of gas block equipment is relatively large in these years.

Air block equipment according to the use of different production raw materials, raw material quality, the technical performance of the core equipment and different production processes, taking sand air block equipment as an

example, the main raw materials include river sand, lime, cement, etc., but also include some auxiliary materials such as gypsum, blowing agent. These raw materials are evenly stirred and injected into the aerated brick mold frame,

after resting, foaming, curing, and then according to user needs, cut into different specifications of different patterns of blocks, plates, etc., and then put into the steam car into the steam tank in high temperature, saturated steam for maintenance, forming light, porous sand aerated block products.

Wait until updated

Thank you for your interest in Zhengzhou Telifu Machinery Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!