Your current location:Home>Product>Mineral processing equipment

Direct deal Quality Assurance Quick response Service worry free

Production capacity:1.9-76t/h

Feed particle size:

Applicable materials:River sand, copper ore, pyrrhotite, hematite, limonite, molybdenum ore, gold ore, iron ore, limestone, clay, etc.

![]() Do you need help? WhatsApp: +8615038150366

Do you need help? WhatsApp: +8615038150366

sales@trifumac.com Hotline:+8615038150366

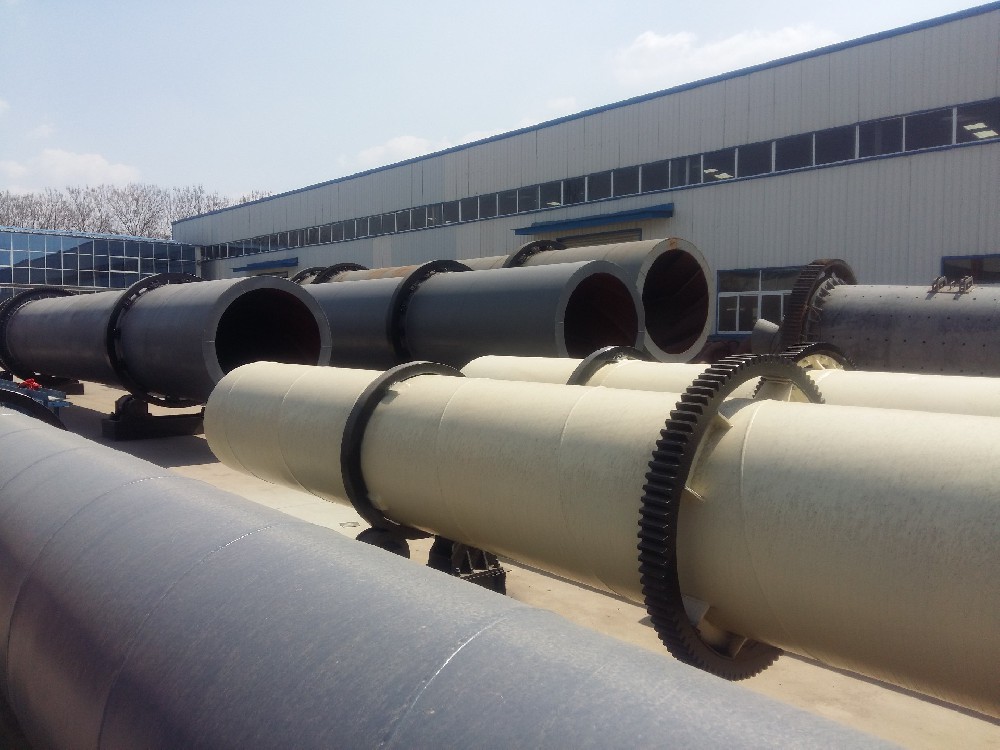

The machine is mainly composed of rotary body, lifting plate, transmission device, support device and sealing ring and other parts. The dryer is a slightly inclined cylinder with the horizontal direction, the material is added from the higher end, and the high-temperature hot gas and the material flow into the cylinder, with the rotation of the cylinder, the material runs to the lower end due to the action of gravity. The inner wall of the cylinder is equipped with a sheet to pick up and sprinkle the material, so that the contact surface between the material and the air flow is increased to improve the drying rate and promote the material forward. The dried product is collected from the lower part of the bottom.

1. Energy-saving processing speed, large processing capacity, less fuel consumption.

2. Low security cost, safe use, with certain protective measures.

3. Strong and durable in the shape of the design using tugs and rolling rings to make it more firm.

4. Stable operation, strong anti-overload ability design of the wheel structure, greatly reducing the horizontal thrust caused by the equipment tilt work. Strong anti-overload ability, stable cylinder operation, high reliability.

The dry wet material is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feed end through the feed pipe by the feed machine of the hopper. The slope of the feeding pipe should be greater than the natural inclination of the material, so that the material can flow smoothly into the dryer. The dryer cylinder is a rotating cylinder that is slightly inclined to the horizontal line. The material is added from the higher end, the heat carrier enters from the lower end, and the material is in countercurrent contact, and the heat carrier and the material are also flowing into the cylinder together. As the cylinder rotates the material is moved by gravity to the bottom end. In the process of moving the wet material forward in the cylinder body, the heat transfer of the heat carrier is directly or indirectly obtained, so that the wet material can be dried, and then sent out by the belt machine or screw conveyor at the discharge end. The inner wall of the cylinder is equipped with a copy plate, which is used to copy the material and scatter it, so that the contact surface between the material and the air flow is increased, so as to improve the drying rate and promote the progress of the material. Heat carrier is generally divided into hot air, flue gas and so on. After the heat carrier passes through the dryer, the cyclone dust collector is generally required to capture the material in the gas. If it is necessary to further reduce the dust content ofthe tail gas, it should also be discharged after a bag dust collector or a wet dust collector.

Specification (Diameter × length) (m) | Barrel volume (m³) | Processing capacity (t/h) | Mounting slope (%) | Maximum inlet temperature (℃) | Main motor (kw) | Total weight (t) | |||

Φ1.2×8.0 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 | |||

Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 | |||

Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 | |||

Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 | |||

Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 | |||

Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 | |||

Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 | |||

Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 | |||

Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 | |||

Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 | |||

Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 | |||

Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 | |||

Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 | |||

Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 | |||

Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 | |||

Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 | |||

Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 | |||

Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 | |||

Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 | |||

Thank you for your interest in Zhengzhou Telifu Machinery Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!